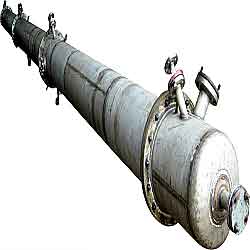

We manufacture highly efficient distillation columns that are designed to achieve highly effective distillation process. These distillation columns are suitable for a variety of industries and are of two types :

Columns, in the context of industrial processes, typically refer to vertical vessels used for various purposes such as distillation, absorption, stripping, and fractionation. Here are some key aspects of columns:

1. Functionality :

Columns are designed to facilitate mass transfer processes, where two or more components are separated based on their differences in volatility, solubility, or other physical properties.

2. Types :

There are different types of columns, including distillation columns (such as fractionating columns and rectification columns), absorption columns, stripping columns, and packed columns, each designed for specific separation processes.

3. Construction :

Columns are usually cylindrical in shape and can be constructed from materials such as stainless steel, carbon steel, or other alloys, depending on the process requirements and the properties of the substances being processed.

4. Internals :

Columns may contain various internal components such as trays, packing materials (like structured packing or random packing), and distributors to enhance mass transfer efficiency and separation performance.

5. Operation :

Columns operate based on principles such as vapor-liquid equilibrium, where the vapor and liquid phases come into contact and exchange components as they flow through the column.

6. Heat Exchange :

Some columns incorporate mechanisms for heat exchange, such as reboilers and condensers, to provide the necessary energy for vaporization and condensation during the separation process.

7. Control Systems :

Columns are typically equipped with instrumentation and control systems to monitor and regulate factors such as temperature, pressure, flow rates, and composition to optimize separation efficiency and product quality.

8. Design Considerations :

Column design involves considerations such as column diameter, height, number of stages or trays, packing type, and operating conditions, which are determined based on the specific separation requirements and process constraints.

Overall, columns play a critical role in various industries, including petrochemical, chemical, pharmaceutical, and food processing, by enabling the separation and purification of substances to obtain desired products with specific purity levels.

Silent features of distillation Columns :

- Great Technology

- Certified Engineers

- Delivery Ontime

- Best Branding